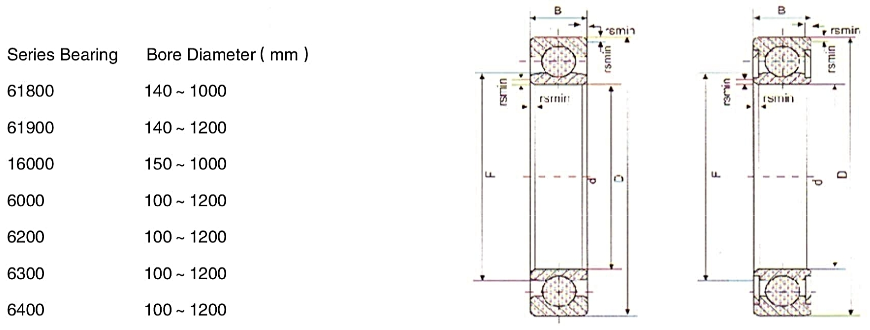

Deep Groove Ball Bearing

The deep groove ball bearing is of the most typical structure in rolling bearing and for extensive purposes. Such bearing can carry both the radial load and the bi-directional axial load. Thanks to the small friction moment, it is most suitable for the working occasion of high-speed rotation, low noise and low vibration.

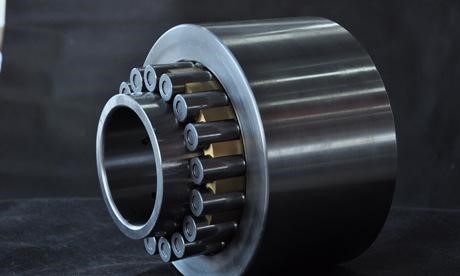

Cylindrical Roller Bearing

The cylindrical roller bearing is a detachable bearing facilitating assembly and disassembly. The cylindrical roller is in the linear contact with the bearing race and has a large loading capacity, capable of carrying large radial and punching loads and applicable to high-speed rotation. Such bearing is in multiple varied structures including single-row, double-row and four-row ones and mainly applied to a wide range of motors, dynamos, combustion turbines, main shafts of machine tools, reducing gears, handing machineries and transporters, therein, the four-row cylindrical roller bearing is mainly applied to the rolling mill.

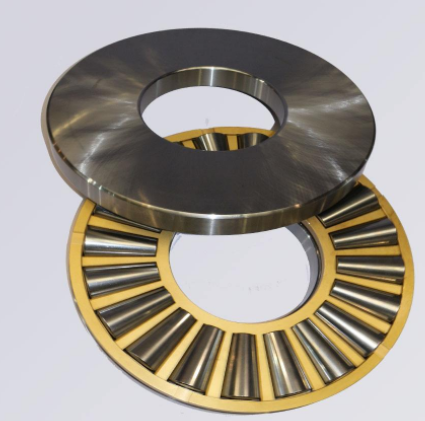

Spherical Roller thrust Bearing

With spherical rollers and races, the thrust self-aligning roller bearing boasts the self-allgning performance. Such bearing has a much large axial loading besides the axial load , not so sensitive to the coaxial degree and the shaft deflection or distortion. Such bearing is mainly applied to hydro generator, vertical machine, marine propeller shaft, tower crane, plastic injection extruder and so on.

Tapered Roller Bearing

For the tapered roller bearing, the inner and outer races are tapered,

with tapered rollers between is mainly used to carry the radical and axial

combined load, mainly the radical load.

The inner components and the out ring of the bearig are detachable,

facilitating assembly and disassembly. The axial loading capacity

of bearing depends on the contact angle α ,the large which is ,

the larger the axial loading capacity will be. Such bearing is

widely applied to automobile,gear box, main shaft of machine

tool, constructional mechanisms, rolling stock and rolling mill joumal.

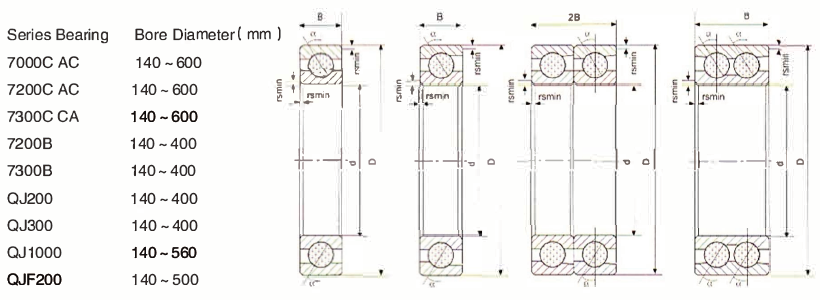

Angular Contact Ball Bearing

The angular contact ball bearing falls in a wide range of structures, e.g .. the single-row onecan carry both the radical load and, with DB and DF combinations composing four-point contact,the radial load and the bi-directional axial load and carry both the radial load. The angular contactball bearing is applicable to high-speed and high-precision rotations.

Such bearing is mainly applied to main shaft of machine, high-frequency motor, oilpump, aircompressor and printer etc. And the four-point contact ball bearing mostly to the roller drum of rolling mill for the sake of carrying the radical load.

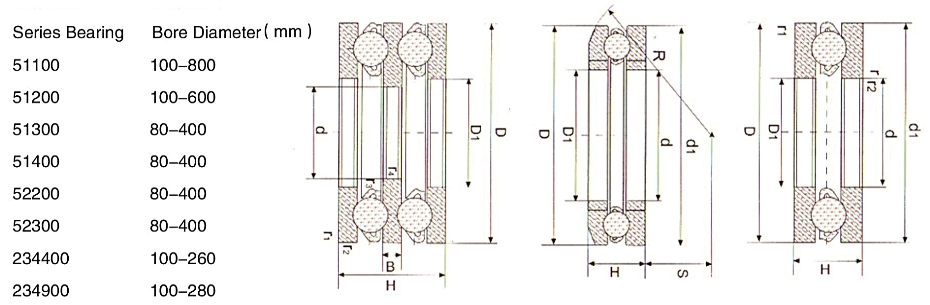

Thrust ball Bearing

The thrust ball bearing falls into two categories, namely the uni- directional one and the bi-directional one. The uni-drirectional bearing can carry the uni-directional axial load and the bi-directional one do the bi-directional axial load. Neither capable of carrying the radical load. The thrust ball bearing must be pre-fastened axially in the work and is mainly applied to automobile steering mechanism, main shaft of machine tool, rubber and plastic machinery and so on. er and so on.